Dry type, Metallized film, Energy density up to 0.25J/cc

Series ESDS

Applications

DElectro-transport, substations, windmills, frequency converters, etc.General

The ESDS series capacitors are specifically designed for DC circuit. The capacitor has low losses and elements are made by self-healing metallized polypropylene film with dry technology. The special composition of polymeric dielectric enables to reach high dielectric strength in the temperature range up to +85°C. The capacitors have excellent operating current and lifetime.Characteristics

| Standard | IEC61071, IEC 61881 |

| Capacitance tolerance | ±10% (optional ±5%) |

| Rated DC Voltage | 900V to 40kV |

| Dielectric | Polypropylene |

| Tangent of the loss angle | < 0.1% |

| Self-inductance (ESL) | < 100nH |

| Test voltage between terminals | 1.5xUn / 10s at 25±5°C |

| Test voltage between terminals and case | 2xUn+1000VAC / 60s at 60Hz 25±5°C |

| Operating temperature | -40°C / +70°C (optional 85℃) |

| Storage temperature | -40°C / +85°C |

| Case | Rectangular non-magnetic stainless steel |

| Filling material | Epoxy resin (RoHS complied) |

| Failure rate | < 100FIT |

| Lifetime Expectancy | > 100000h |

| Cooling method | Natural |

Specification and Dimensions

| Un (DC) | uF | L (mm) | W (mm) | H (mm) | Weight (kg) |

|---|---|---|---|---|---|

| 900 | 4000 | 340 | 125 | 215 | 11.1 |

| 8000 | 125 | 340 | 18.2 | ||

| 16000 | 175 | 430 | 29.7 | ||

| 24000 | 175 | 580 | 40.4 | ||

| 1200 | 2000 | 125 | 215 | 11.0 | |

| 4000 | 125 | 380 | 20.5 | ||

| 8000 | 125 | 650 | 35.5 | ||

| 12000 | 175 | 670 | 47.3 | ||

| 2000 | 1000 | 125 | 270 | 14.0 | |

| 2000 | 125 | 440 | 23.3 | ||

| 4000 | 175 | 580 | 40.7 | ||

| 5000 | 175 | 700 | 49.4 | ||

| 4000 | 200 | 125 | 240 | 12.4 | |

| 400 | 125 | 400 | 21.4 | ||

| 800 | 175 | 500 | 35.2 | ||

| 1000 | 175 | 580 | 40.7 | ||

| 5000 | 150 | 125 | 285 | 14.8 | |

| 300 | 140 | 430 | 24.6 | ||

| 600 | 175 | 540 | 38.2 | ||

| 750 | 175 | 650 | 46.3 |

| Un (DC) | uF | L (mm) | W (mm) | H (mm) | Weight (kg) |

|---|---|---|---|---|---|

| 5500 | 100 | 340 | 140 | 215 | 11.6 |

| 200 | 340 | 140 | 360 | 20.4 | |

| 400 | 340 | 175 | 470 | 32.5 | |

| 600 | 340 | 175 | 650 | 45.4 | |

| 6500 | 200 | 340 | 185 | 330 | 24.1 |

| 400 | 530 | 185 | 400 | 42.9 | |

| 600 | 530 | 185 | 550 | 59.9 | |

| 800 | 530 | 185 | 710 | 78.4 | |

| 10000 | 50 | 340 | 185 | 220 | 15.3 |

| 100 | 340 | 185 | 380 | 28.0 | |

| 200 | 530 | 185 | 470 | 54.4 | |

| 300 | 530 | 185 | 660 | 77.8 | |

| 20000 | 10 | 340 | 185 | 240 | 17.2 |

| 20 | 530 | 185 | 280 | 31.1 | |

| 40 | 530 | 185 | 490 | 57.4 | |

| 60 | 530 | 185 | 690 | 82.3 | |

| 40000 | 2 | 340 | 185 | 300 | 21.8 |

| 4 | 340 | 185 | 490 | 36.1 | |

| 6 | 530 | 185 | 400 | 46.3 | |

| 10 | 530 | 185 | 570 | 66.9 |

Reference Dimensions

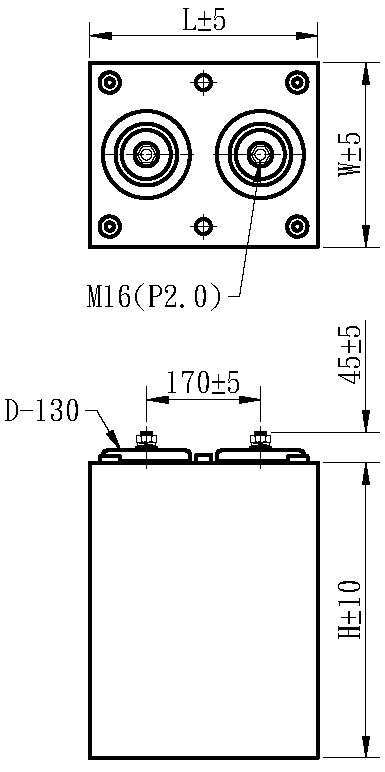

Fig-1

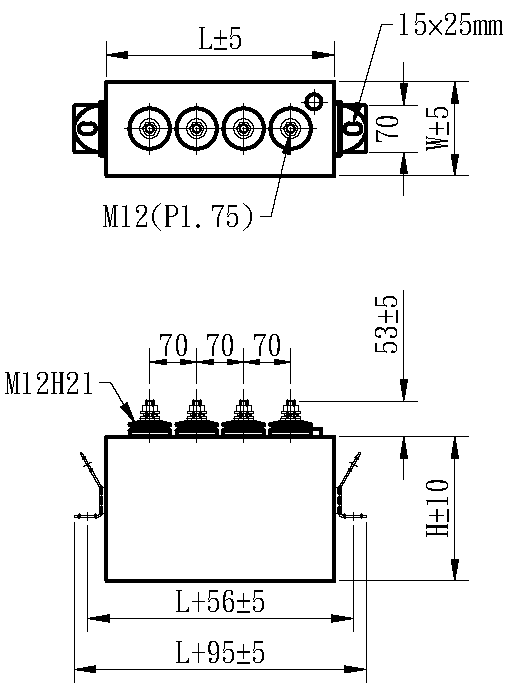

Fig-2